Eucalyptus Species

K58

Planting trees Stems straight, dark red, large leaves, wide base, pointed tip, smooth leaves.

Wood grown The trunk is straight and round, brown bark, small branches, very branched branches, frequent branches without grooves, wide bushes, thick dense bushes. Can cover the grass well.

Specification Good weight tree Grows well in Loamy soil, Sandy loam Sticky loamy sand Flat land and at the foot of the hill Deep soil will continue to grow. High growth rate and weight gain during the age of 4 – 5 years

Restriction Should not be planted with Effusion and areas with shallow soil. The soil is tight and has soil layer. The tree will have symptoms. Dry peaks lacking water Broken trunk in the dry season.

K7

Planting trees Stems at the top of the pink to dark red. The leaves are pointed at the edge, the leaves are wavy.

Wood grown The trunk is straight, the branches are medium-sized, the branches are loose, and the branches naturally are not good.

With grooves under the branches, wide, thick leaves

Specification Grows well in loamy loam, sandy loam. The loamy loam likes the plains, the lowland or the lowlands with good drainage.

Restriction Do not like shallow soil, have a layer of soil, do not like high areas at the foot of the mountain.

K62

Planting trees The trunk is straight, brown top, medium sized leaves, wide base, pointed tip, smooth leaf edge.

Wood grown The trunk is round, brown bark, small branches, frequent branches without grooves under the branches, wide shrubs, dense leaves.

Specification Good weight tree Grows well in loamy soil Sandy loam Sticky loamy sand Suitable for flat plains and hilly slopes with deep topsoil’s Drain well Especially in the rainy season without waterlogging

Restriction Should not be planted with waterlogged and areas with shallow soil. The soil is tight and has soil layer. The tree will be dry and dehydrated. Broken trunk in the dry season

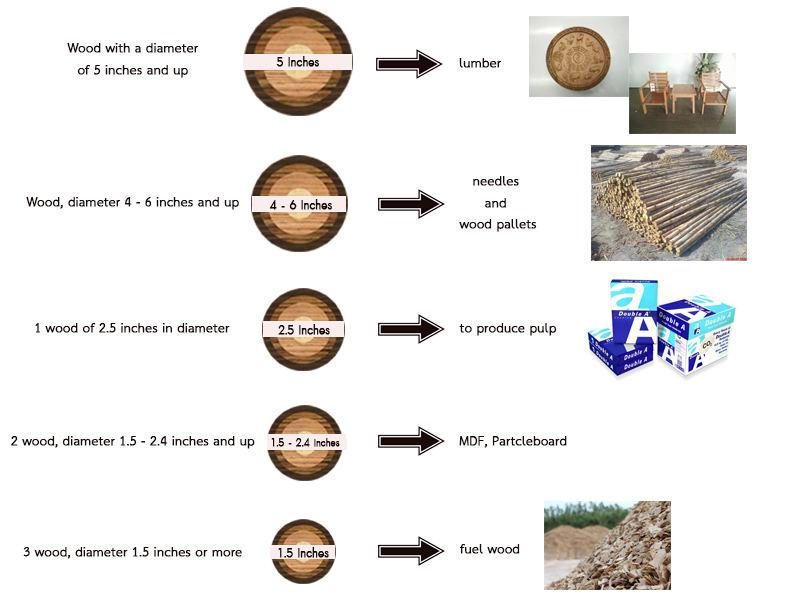

Wood size produced from factory

Wood chips from the factory

Chopping Peeled wood

Wood chopping, peeling There are 4 lines of wood chips chopping and peeling machine production lines. Which can produce up to 1,230 tons/day of wood chips, 36,900 tons/month or more than 442,800 tons/year in order to be sufficient for exporting to customers in order to produce into pulp and for foreign exports.

Chopping Not Peeled wood

Wood Chopping Work, there are 2 lines of chopping and peeling machine for production lines. They can produce as much as 285 tons/day, 8,550 tons/month or 102,600 tons/year, to be sufficient to be used for making Rigid fiberboard High density, Gypsum fiber boards, Cement veneer and fuel.

Bark

Bark of the Laem Khao Wood Chip Factory derived from peeling eucalyptus logs, in order to separate the log pieces, peel and bark. After that, the bark will be sent into the stock of bark products with up to 270 tons / day, 8,100 tons / month and 97,200 tons / year for use as fuel to burn, electricity and generating electricity.